Compass CapstoneTeam

ME Capstone for the Compass Group at NU

My Team and I were tasked with picking up from where another capstone team left off. Our task is to redesign, fabricate, and test a plastic recycling system for Compass Group

(the provider of NU's food services). The shredder subsytem was to be built from scratch, an off the shelf dishwasher and injection molder were purchased,

and a mold was designed for the injection molder. Initially, the team was tasked with designed a cleaner subsystem from scratch, however, after research was done into water usage by the team's

cleaner alpha prototype and a commercial countertop dishwasher, it was realized that the commercial dishwasher was six times more efficient in terms of water usage than the alpha prototype.

My role on the team was as the Client Contact and as a Machinist/Designer. As Client Contant I maintained communication with our client, keeping her updated on the project status throughly weekly emails and organizing

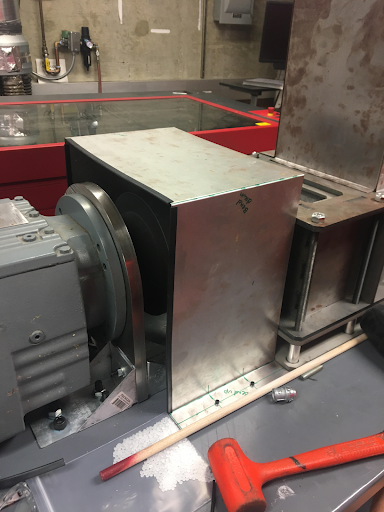

meetings with her and the rest of team. As a machinist I was given parts that needed to machined for the shredder subsytem. This primarily involved waterjetting a riser plate for the shredder, validating designs for a CNCed

motor mount, and facing riser mount tubes to a 0.003" tolerance. As a designer I designed (an manufactured) a hopper cover to the input of the shredder and a motor coupling cover.

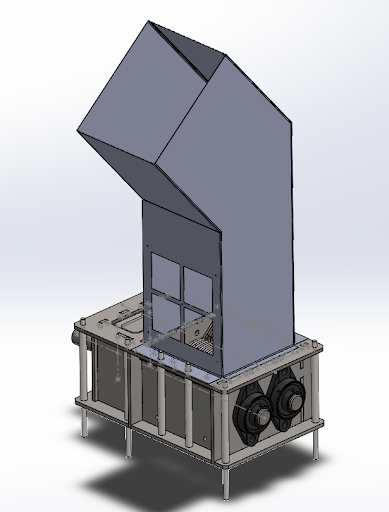

Images of the entire shredder system can be seen below.

Language: N/A

Environment: SolidWorks

Skills: CAD, Rapid Prototyping, WaterJet, Lathe, Sheet Metal Fabrication, Teamwork, Leadership